How to Make Cold Pressed Juice: A Step-by-Step Guide

Learn how to make cold pressed juice with your Juiced Rite commercial juicer with these step-by-step instructions.

Ever wonder how your Juiced Rite Cold Press Machine came to be? Your press arrived shiny and ready to make juice in your shop, but it didn’t start out that way.

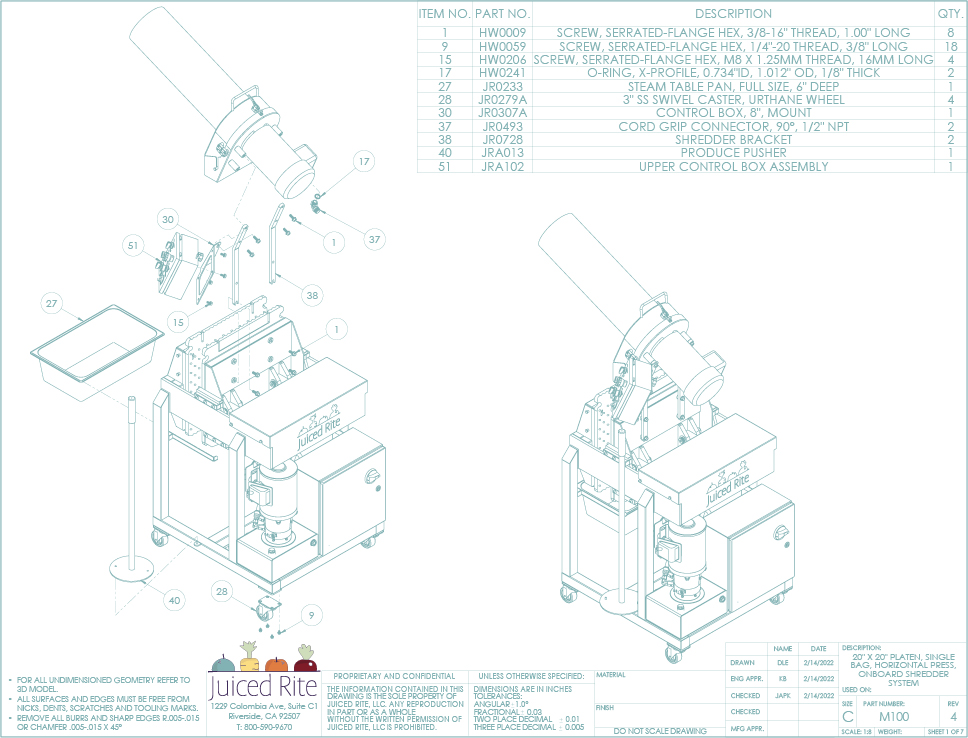

Before we build, we design. These shiny stainless steel juice machines start in our heads and make their way to the computer where they become strategic lines and angles. Our designs reflect efficiency and durability. Easy maintenance and owner servicing are also very important factors we include when creating the design that becomes your amazing machine.

We start like most great ideas, using our experience, ingenuity and problem solving to build the features of the press. Taking into account improvements that will create an even better experience for our customers, our drawings are the blueprints to great machines.

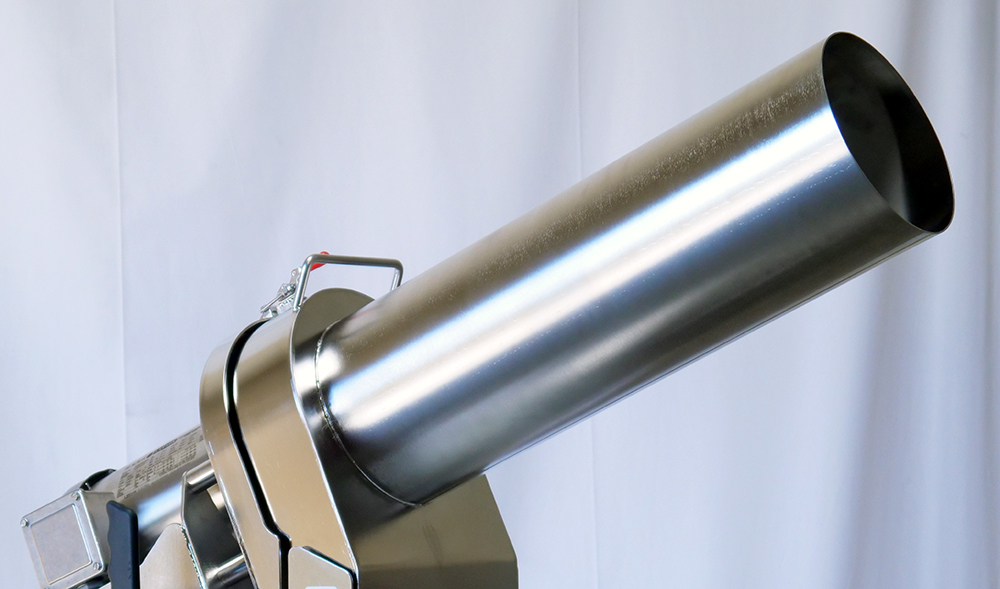

Similar to most manufacturing facilities, we start with raw materials and custom-created parts right here in the USA. Stainless steel sheets, rods and tubes are cut and welded with utmost precision to become parts for the final machine.

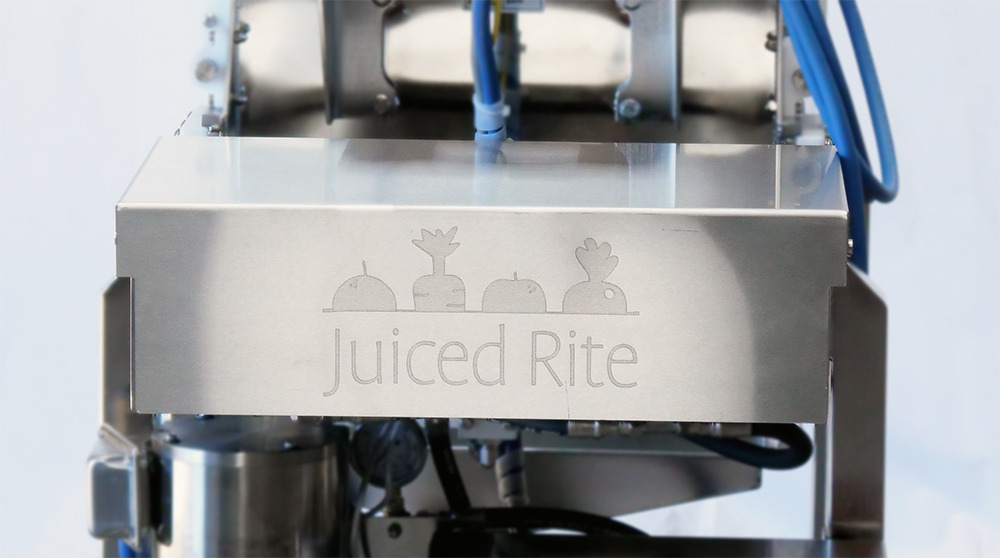

What’s dissimilar to most manufacturing facilities is our small production facility. We build each machine with a hands-on approach. Every machine travels through our facility and is referenced by name of it’s new owner. We pride ourselves in this team-oriented environment, quality checking through each department. No assembly lines here.

Once the machine parts are created, processed and welded, they are shipped off to electropolish to become the shiny machine parts you know and love. The high-quality electropolish process passivates the metal to create a strong and food-safe surface that resists scratches and fingerprints. (Curiosity tingling? Learn more about electropolish here!)

What do you do with all those shiny parts, electrical components and hardware? Why, you put together a Cold Press Juice Machine, of course!

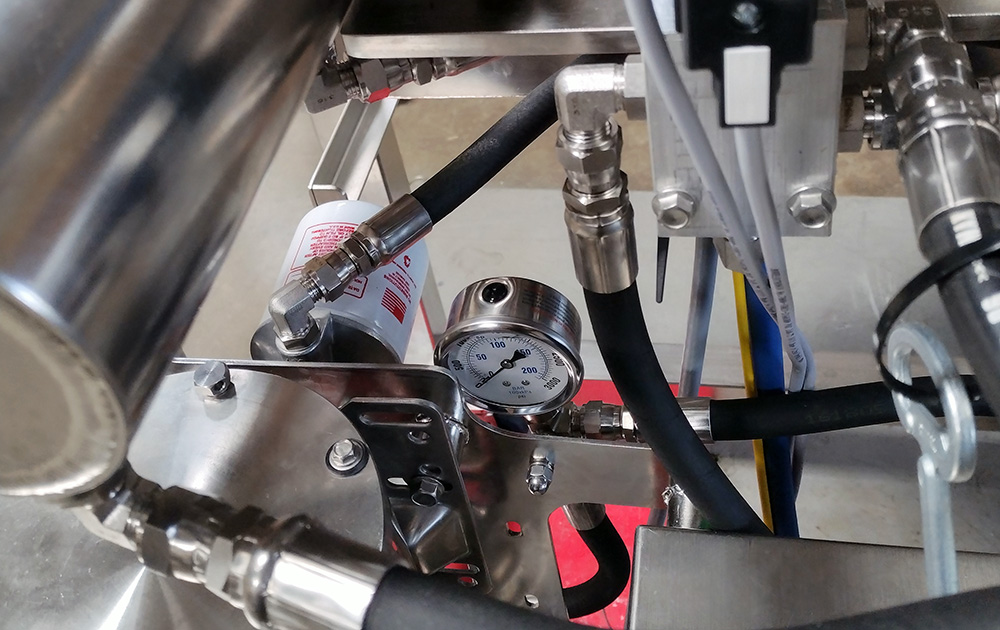

Along with the drives and relays, hydraulics and motors and more are connected and everything gets wired up. Buttons? Check. Emergency stops? Safety sensors? Check and check!

And not only are our presses shiny, they’re smart too! Each cold press machine is equipped with drives and relays, onboard computer components that run our proprietary Pulse Press Program and Speed Control (among other things). These amazing features can help you increase your yield automagically (you know you want to learn more about that here in our Getting to Know Your Machine video).

Throughout the assembly phase, each machine has a dedicated technician assembling and testing as it moves closer to completion. Once we have a fully assembled press, it’s filled with fluid and powered on for the first time (we still get goose bumps)!

The only thing more exciting than finishing a machine is sending it off to you! After testing, we lovingly package your machine.

Sometimes we get a chance to travel with our machine and introduce it to it’s new home (and teammates), which is pretty exciting. Every new machine has the option of a Set Up and Training where we arrive on location and get you – you guessed it – set up and trained (contact our non sales sales team at 800.590.9670 or 909.464.8253 ext 1 or email them at sales@juicedrite.com)!

Our team is really important to us, so much so that we refer to ourselves as a family (full disclosure – there are some of us who are legit from the same parents!). All of these amazing people contribute to the final cold press machine that joins your family too! Learn more about this amazing crew here.

Happy Juicing!

We’ll send new article alerts & product updates.

| Thank you for Signing Up |

Learn how to make cold pressed juice with your Juiced Rite commercial juicer with these step-by-step instructions.

In this article we discuss the ideal use and merits of each blade available through Juiced Rite.

Learn more about our Onsite Set Up & Training and how we live the #vanlife to get your machines delivered to you!