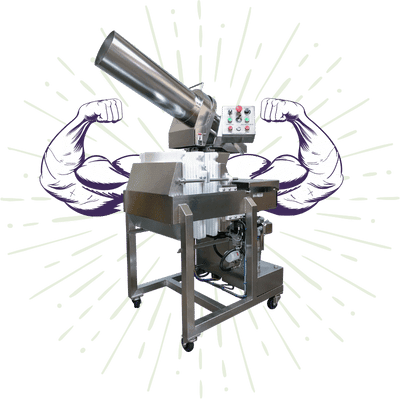

Commercial Cold Press Juicers

- High Yield

- Efficient

- Auto Press

What is a commercial cold press juicer?

A commercial cold press juicer is a heavy-duty machine designed for high-volume juice production, typically used in juice bars, cafes, restaurants, grocery stores, breweries, farms, vineyards and many other food manufacturing businesses that produce fresh juices in large quantities. Whew! That’s a lot!

Juiced Rite juicers make it easy to press more juice in less time, helping your business meet production goals. Our machines keep heat to a minimum during the juicing process, which is key to making the best, high-quality cold-pressed juice. Quality juice in less time is why Juiced Rite is the top choice manufacturer for premium large-scale commercial production!

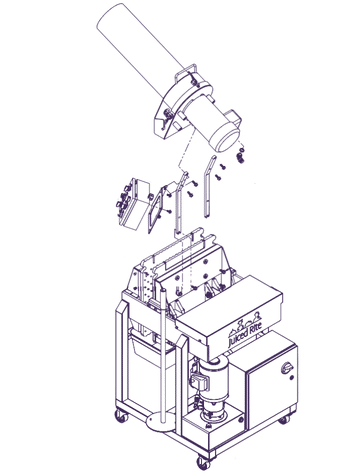

How does a commercial cold press work?

Commercial cold press juicers are designed to maximize juice yield. They can extract more juice from the same amount of produce compared to standard juicers, making them more efficient for commercial use. Regular cleaning & maintenance are essential to prevent clogging & keep it running smoothly for a long time.

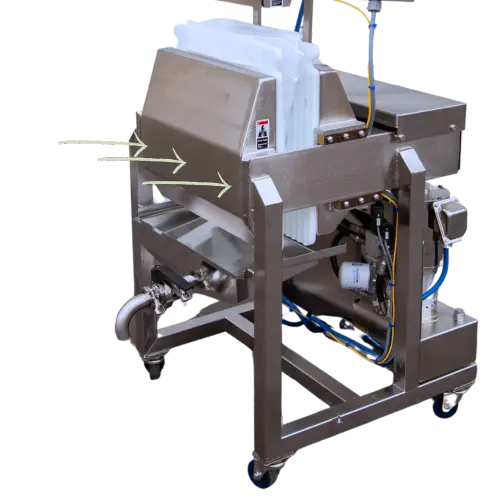

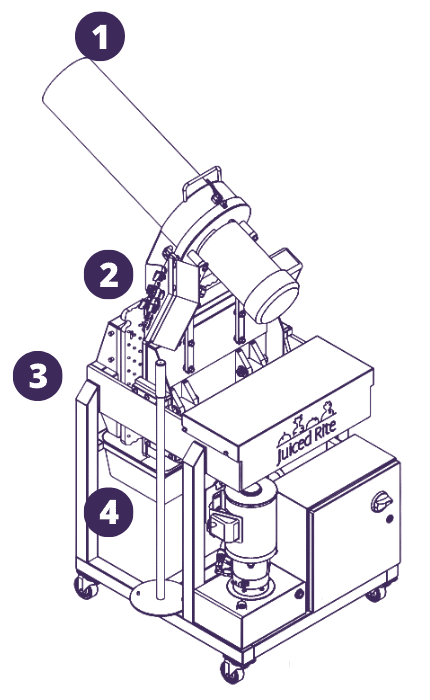

FEED & SHRED THE PRODUCE

Fruits and vegetables are fed into the machine manually down the shredder chute and the produce is shredded into chunks. Some commercial cold presses can handle large quantities at once, reducing prep time.

COLLECT THE PULP

The ground produce is then transferred into a mesh press bag that sits in the hydraulic press zone. This bag holds the pulp in preparation for the press cycle. In commercial models, this is typically done with minimal manual handling for efficiency.

RUN THE HYDRAULIC PRESS

The machine then applies high pressure to squeeze out the juice. This pressing action ensures that every drop of juice is extracted and separated from the pulp.

Collect THE juice

Finally, your fresh, cold-pressed juice flows from the press into a juice collection pan, ready to be bottled, stored, or further processed. The leftover pulp remains in the press bag and can easily be discarded or repurposed.

Shop Juiced Rite Commercial Cold Press Juicers

M75

Commercial Cold Press JUicer

10-30 gallons of juice per hour

106-320 bottles (12oz) per hour

108-322 bottles (350ml) per hour

M100

Commercial Cold Press JUicer

20-40 gallons of juice per hour

212-424 bottles (12oz) per hour

214-428 bottles (350ml) per hour

M200

Commercial Cold Press JUicer

30-80 gallons of juice per hour

318-848 bottles (12oz) per hour

314-857 bottles (350ml) per hour

It’s also wonderful to produce so much juice in a small amount of time."

Industries That Thrive with Commercial Cold Press Juicers

Cafes & Restaurants

Delight your customers with cold press juices, shots & cocktail drinks.

BReweries & wineries

Elevate your wines & ciders with fresh-pressed flavors that pack a punch.

Farms & Orchards

Turn your local harvest into delicious seasonal

farm-to-table products.

Grocery & Health

Food Stores

Squeeze your "ugly"

produce into the most delicious juices around.

Food Innovation

Education

Equip the next generation of food producers with the finest cold press technology.

Wholesellers

& Copackers

Scale production and

elevate quality without missing a beet!

Yoga Studios &

Fitness Centers

Nourish the souls of your health-conscious customers with vibrant & natural flavors.

Nut & Plant based Milk producers

Create smooth, high-yield nut and plant mylks with cold pressing for pure, fresh, and creamy results.

Alternative product manufacturers

Ideal for botanical extracts, alternative flours, and other non-juice plant-based products.

Cannabis & cbd

product makers

Separate your THC and CBD from the solid plant fibers using a cold press process.

What can YOU do with the right Juiced Rite cold press?

Better juice production starts with

understanding your business needs:

our questions and knew the machines thoroughly."

Frequently Asked Questions

What types of fruits & veggies can your commercial juicers process?

Juiced Rite juicers handle all kinds of fruits and veggies—soft, hard, or fibrous! They’re perfect for high-water produce like apples, carrots, and leafy greens, but just make sure to avoid anything with pits, large seeds, and a low water content.

Fruits like avocados, bananas, and some stone fruits are good examples of the kinds of produce that should not be shredded or pressed with our juicers. They’re too creamy or starchy, have low water content, and can cause damage to your juicer’s components. Stick with the juicy stuff, and you’ll be all set! (And reach out to us with any questions!).

If your recipes include these ingredients, blend them separately and mix them in with your freshly pressed juice.

What makes a cold press juicer different from your average juicer?

Unlike centrifugal and masticating juicers, commercial cold press juicers are made to handle constant use, quickly process lots of fruits and veggies, and stay cool without overheating. They’re a must for businesses that need to crank out fresh juice all day long.

Can a cold press juicer enhance the flavor of my juices?

One of the best things about using hydraulic cold presses is that they introduce little to no heat during the juicing process. This means your juice stays as true to its ingredients as possible without the insoluble fibers in the mix.

Many of our customers are amazed by how rich their flavors are after switching to our cold press juicers. In fact, some even adjust their recipes because the natural flavors are so vibrant, they don’t need to add as much flavoring anymore – a win-win in our book!

How long can I expect cold-pressed juices to last after bottling?

Please check your local & state regulations, as the answer varies from state to state and country to country! The general rule of thumb is that raw pressed fruit & vegetable juices have a shelf life of about 3-7 days depending on the produce used, how it was handled and processed, and how it’s stored.

Generally, it’s recommended that cold press juice be consumed immediately after purchase or refrigerated and consumed before its official expiration date.Visit your local FDA & HCAAP guidelines to find an answer that’s standardized and appropriate to your particular area.

The upfront cost of commercial juicers is high. What can I expect from this investment?

Commercial juicers have a high upfront cost, but the benefits are worth it. With Juiced Rite cold pressing equipment, you’ll get a reliable, long-lasting machine that simplifies your juicing process and handles tough fruits and veggies with ease. This means less prep time and more of the juice your customers love, faster.

Over time, the right machine will pay for itself — making it a smart and worthwhile investment for your business operations! The most important thing is to invest in a juicer that’s reliable, fits your current demand, & gives you room to boost production as your business grows.

Can a Juiced Rite commercial juicer help my business succeed?

Absolutely! The right commercial juicer, one that fits your juicing needs and leaves room for growth, is exactly what most juice businesses need to succeed – it’s at the heart of your product. When you’re making hundreds of bottles of juice daily, a commercial cold press will save you on labor and boost productivity, reducing the amount of hands-on processing that’s so familiar to small-scale juice businesses.

Are Juiced Rite juicers NSF-certified for commercial kitchen use?

Yes! Having a NSF certification means our juicers meet the safety and cleanliness standards for commercial kitchens when they’re properly and regularly maintained. It gives us confidence that our machines are food-safe for raw juice production as defined by experts in the field.

Can you help me choose a Juiced Rite juicer?

Absolutely – it’s what we love to do! Fill out this form & our team will reach out to you as soon as possible. Together, we’ll discuss your needs & wants, business goals, and finally match you with the Juiced Rite cold press that is just right for your business.

Not ready to meet with us yet? Take our Matchmaker Quiz to get one step closer to your answer! We can always connect after for a more tailored juicing solution.

Can I schedule a demo and see a juicer in action?

We’d love to have you! Our headquarters is in Riverside, CA, and we also offer convenient virtual demos over Zoom. During the demo, we’ll show you the machine in action, highlight its features, and test it with any produce or recipe you’re excited about. If you’d like to schedule a demo with us, fill out our contact form and we’ll get in touch with you as soon as possible!